W-977 Assembly Instructions:

W-977 Factory Reset:

Weaver® Wheel Balancers Mounting Instructions:

W-977 Distance Arm Calibration:

W-977 Wheel Balancer Calibration:

New Style W-MJ II Motorcycle Adapter Kit:

Wheel Balancer Truck Kit:

Weaver® W-977 ALU Modes:

W-977 Sensor Testing:

Troubleshooting Wheel Balancer Error Codes:

Wheel Balancer Video Transcripts

W-977 Quick Start Guide Transcription:

Welcome to DerekWeaver.com. In this video, we will discuss receiving, unpackaging, and assembling your W-977 wheel balancer.

When your W-977 arrives, it will be packaged in a crate similar to this crate. Prior to signing the delivery receipt, inspect the crate for damage or irregularities and note that on the delivery receipt. Your crate will have an address label with your address. It will have an orange warning label that tells the freight company to handle the crate with caution. You'll have a white warning label that tells you to inspect the crate before signing the delivery receipt and note any damage on the delivery receipt, and a green label that tells the freight company not to stack the crate.

To remove the top of the crate from the skid, loosen the 10 tabs around the bottom of the crate. After the 10 tabs are loosened, you can remove the top of the crate. Now we will remove the top of the crate - you may need assistance for this step.

Remove the remaining packaging material and take inventory of the items in the crate. You should have a small box with the hood part of the hood assembly, a large box, which is an accessory box, and the hood, and, of course, the wheel balancer itself.

You can now unbolt the balancer from the skid. Remove two handles from the accessory box and install them on the left-hand side of the machine to be used as solid lifting points for removing the wheel balancer from the skid.

Now we can remove the wheel balancer from the skid.

We're going to start the assembly by installing the hood. Begin that by removing the four Allen bolts from the back of the machine using an 8-millimeter Allen wrench. Once you've removed the hood bracket from the small box, you can install it on the back of the machine where you remove the four Allen bolts. Once the hood bracket is installed and plug the two wires from the hood switch and the two wires protruding from the back of the machine, really remove the Allen bolt from the hood shaft and remove the protective Styrofoam from the hood switch.

Now we will install the hood on the hood shaft. Continue sliding the rod into the shaft until it's firmly on. Once the hood is fully on the hood shaft, you can rest it on its open stop. Install the Allen bolt back in the hood shaft to keep the hood on. Tighten it with an 8-millimeter Allen wrench and install the hood spring which you'll find in the accessory box.

Now we will install the three remaining accessory handles and the tool holder snaps into place. The final step of the installation is to install the 40-millimeter shaft. You tighten until it's hand tight and then we use an 8-millimeter Allen wrench in the screw hole to cement the shaft.

Now we will define the key function for the W-977:

- The DYN/STA key allows you to enter the dynamic mode or the static mode.

- The ALU key allows you to enter one of four standard alternative weight placement modes.

- The ALU* key allows you to enter machine-defined alternative weight placement, in which case you will use the distance gauge to place your stick-on weights.

- The matching key allows you to match the heavy side of a wheel to the light side of the tire.

- The CAR/MOT key allows you to enter the car mode of the motorcycle mode.

- The weight split key allows you to split weights and hide them behind spokes for a more aesthetically pleasing look.

- The Millimeter/Inch key allows you to use millimeters or inches.

- The people key, when pushed briefly, shows you the exact amount of imbalance of a given tire wheel assembly. When held for 6 seconds, it allows you to enter the calibration mode.

- The Gram/Ounce key allows you to change from ounces to grams.

- The house key allows you to enter the program mode and allows you to define user settings for one of four users.

- The DIS plus and minus key allows you to change the distance.

- The BRE plus and minus key allow you to change the wheel width.

- The DIA plus and minus key allow you to change the wheel diameter.

- The stop key stops a spin cycle and the start key starts a spin cycle.

Your W-977 wheel balancer is assembled and ready for use. Prior to balancing your first wheel, we recommend calibrating the machine.

Thank you for choosing DerekWeaver.com for all your automotive equipment needs.

W-977 Wheel Balancer Distance Arm Calibration Transcription:

Hi, and welcome to DerekWeaver.com. In this video, we'll be detailing the calibration of the distance arm on the W-977 wheel balancer.

First step in calibrating the arm is to press the HOME key once. Press the DISTANCE key once and press the HOME key twice. The display will read POS and a position indicator here, rotate it until it's at 110. Press the PEOPLE key and then rotate it until it reads 130. Press the PEOPLE key again. Now it reads CAL DAS. At this point, we'll hit the HOME key once and it will zero the arm at rest, so the arm should be at rest here. Press the HOME key again. Now that reads FAC 150. We will pull the arm out until the gauge reads 150 and press the HOME key.

When we release the arm, it will go into the diameter calibration. Press the HOME key and with the arm located at the stub of the shaft, press the HOME key. Next, we'll bring the arm to the bead seat on the rim, in this case we have a 15-inch wheel we're using for calibration, so we're going to change the diameter to 15 and then press ENTER or the HOME key and that stores the data for our arm. At that point, check the arm. It should read the diameter and the distance correctly on the display. You will need to input the width manually.

That concludes the calibration of the distance arm on the W-977 balancer. Please also watch our video on the calibration of the balancer itself and thank you for choosing DerekWeaver.com.

W-977 Wheel Balancer Calibration Transcription:

Hi, and welcome to DerekWeaver.com. In this video, we're going to detail the calibration of the W-977 balancer. In order to do that, you'll need a 14, 15, or 16-inch wheel in good condition, not necessarily balanced, but in good condition.

First thing we need to do is put the parameters of the wheel in correctly. If you haven't done so already, it would be a good idea to watch the video on the calibration of the distance arm for the W-977. It is an automatic data entry arm, so by pulling the arm out and holding against the bead seat it automatically puts the distance and the diameter of the wheel in for you. The only manual entry you'll have to put in is the width using the rim width calipers.

The next step in the calibration is to press the HOME key. It’ll read “Set Opt.” Next, DISTANCE up, next HOME key twice. Now it reads “position” and it gives you a number indication on the right side of the display. We're going to rotate the tire and wheel assembly till we get to 110. Hit the PEOPLE key and rotate to 120. Hit the PEOPLE key again and this display changes to “Add” “0.00.” We're going to spin the tire wheel assembly with nothing on it simply by lowering the hood. We're going to take our three-and-a-half-ounce calibration weight that was provided with the balancer, line the location up on the right or outer plane directly at 12 o'clock. Paying close attention to that location will help the accuracy of the calibration. Next, we'll spin the balancer. At this point, we'll remove the calibration weight from the right plane, line our location up on the left plane, and hammer the calibration weight precisely at 12 o'clock. Spin the balancer again. It will save the data and the balancer is calibrated.

After calibrating your balancer, it'd be a good idea to balance a tire to verify that the machine is indeed working properly and then imbalance the tire to see whether or not the machine is measuring the imbalance correctly. To do this, we’ll balance the tire.

Once we verified that the tire is balanced, next we'll take a known weight, in this case we're using a two-ounce weight, and we'll just hammer it on our wheel anywhere and spin the machine up. If the machine is working properly, it should read the weight amount within a quarter of an ounce of what you put on and also the location should be correctly at six o'clock. You can verify both planes by then removing the two-ounce weight from the inner plane, hammering it on the outer plane, and doing the same test.

Also line up the location indicators to make sure that your two-ounce weight does indeed show up at 6 o'clock. This concludes the calibration procedure for the Weaver W-977 balancer.

Thank you for using DerekWeaver.com for all your automotive equipment needs.

W-977 Factory Reset Transcription:

Welcome to DerekWeaver.com. In this video, we're going to perform a factory reset to restore all balance critical settings on the W-977 wheel balancer.

Begin the factory reset by hitting the “stop” key, which clears the machine. Hit the house key, and you'll see "set opt" in the window. Hit the DIS+ key and you'll see “set up” in the window. Hit the house key two times and you'll see “tES,” “POS,'' and then a number in the outer window. Rotate the shaft until the number in the outer window shows 111. At that point, hit the millimeter inch key, rotate the shaft until the one window at the outer window shows the number 55, and hit the millimeter inch key, and then rotate the shaft back to 111 and hit the millimeter inch key. You'll see “COd” “SET.” At that point, hit the house key, and you'll see a number in the outer window and a number in the inner window.

We're concerned with the inner window. That number should be 46 and you adjust that number using the DIS+ and DIS- key. Once the number is 46, hit the house key. In this window, you'll see “b-A” and then “POS.” This particular measurement is taken by moving the distance gauge to the flange as if you were measuring a wheel.

And note on the distance gauge the measurement. In this particular instance, the measurement is 215, so we replace the distance gauge and using the DIS+ key, we'll change that dimension to 215. Then hit the house key. You'll see “EL1” in the inner window and a number in the outer window. The outer window should show the number 7 or 007. We change that number using the DIS+ or DIS- key until it shows 007. Hit the house key. At this point, you're finished with the factory reset and you can either turn the machine off or you can hit the DIA+ key which will save those settings. And that completes the factory reset for the W-977 wheel balancer.

Thank you for choosing DerekWeaver.com for all your automotive equipment needs.

Weaver® W-977 ALU Modes Transcription:

Welcome to DerekWeaver.com. In this video, we will video we will demonstrate the special ALU feature of the W-977 balancer. This feature combined with the auto data set arm will help to precisely place the two adhesive weights during an ALU balance.

In order to use the special ALU function on the 977 balancer, you're going to take several measurements. The first one is going to be here, on the outer edge of the rim, and then here, on the inner edge of the rim. You're also going to use the special arm to hold the weight to help precisely position the weight in both locations. We will activate it by pressing the ALU* key here it will display ALU* here.

You’ve already properly mounted a tire and wheel on the balancer. Now you will use the auto data set arm and two locations to precisely pinpoint where you want to put the weights.

First, we'll bring the arm out to the first location and press the house key. Hold it in place until we have a reading and then move it to the second location for the weight and hold it until we have a reading. It's now ready to spin.

In order to use the arm to precisely position the weights, first we will find the location, step on the spindle lock to hold the location, place the adhesive weight in the arm, remove the adhesive, and then use the small window here for distance to precisely place the weight where it belongs at zero. We'll do the same thing for the inside. Bring it to the location, step on the spindle lock to hold it in location, place our adhesive weight on the arm, and then also use the distance to bring it to zero for the precise location, and then spin the balancer. And there you have a balanced wheel using the special ALU function of the W-977 balancer. The use of the special ALU feature along with the auto data set arm will make the placement of stick on weights much easier. Thank you for using DerekWeaver.com for all your automotive needs.

W-977 Sensor Testing Transcription:

Welcome to DerekWeaver.com. In this video, we’re going to demonstrate the sensor testing for the W-977 wheel balancer. Begin the testing procedure by hitting the stop key to clear the machine. Then hit the house key, the DIS+ key, and the house key 2 times. In this mode, we’ll test the shaft position sensor. Rotate the shaft until you see zero in the outer window, and you’re going to rotate the shaft 360 degrees looking to make sure that the number in the outer window increases by single-digit increments. If you see a point during the rotation where the number increases by more than one digit or you see flickering in the numbers, the shaft sensor is likely bad.

When you go through this process, you have to turn the shaft very slowly to see each digit and the final number is 255 and then back to zero. Next, hit the house key. At this point, you will test the static sensor. The static shaft sensor. The number in the outer window should be between 450 and 550. It’s okay if it flickers as this one is. It appears the number is 498 on this machine and that’s within the range that it should be.

Hit the house key and we’ll test the dynamic shaft sensor and again in the outer window, the number should be between 450 and 550. It looks like it’s 525 on this machine and the flickering is okay, just as long as the number is between 450-550. Hit the house key and on the 977 we check the distance gauge. We put the distance gauge in the home position, so up against the machine, and the number in the outer window should be between 28 and 38. This one is 35 and hit the house key again and we’ll check the diameter potentiometer. Place the distance gauge against the shaft housing. With the distance gauge against the shaft housing, the number in the outer window should be 28 to 38. It’s 33 in this case.

And that completes the sensor test on the W 977 wheel balancer. Thank you for choosing DerekWeaver.com for all your automotive equipment needs.

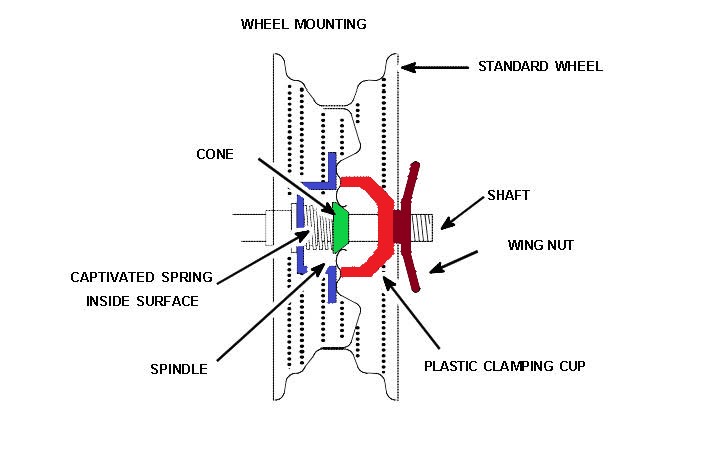

Weaver® Wheel Balancers Mounting Instructions Transcription:

Welcome to the Derek Weaver Company. In this video, we're going to detail the proper mounting techniques for the provided adapters with all of our balancers as well as some optional mounting adapters. View the full transcript here.

New Style W-MJ II Motorcycle Adapter Kit Transcription:

Welcome to DerekWeaver.com. In this video, we will discuss some minor assembly changes to the W-MJ 2 motorcycle adapter. We'll start by unpackaging the motorcycle kit and describing the components. View the full transcript here.

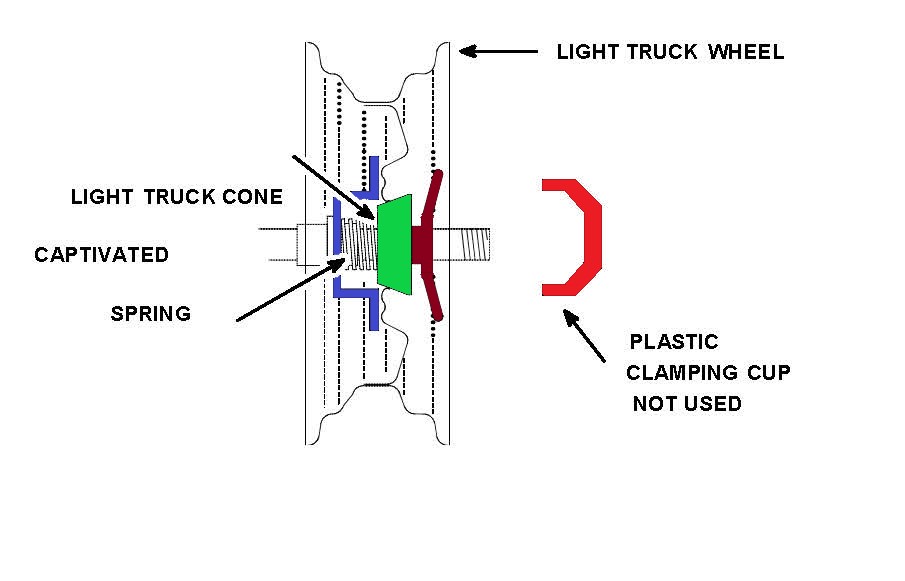

Wheel Balancer Truck Kit Transcription:

Welcome to DerekWeaver.com. In this video, we will show the components and demonstrate the assembly of the Weaver Truck Kit. View the full transcript here.

Troubleshooting Wheel Balancer Error Codes Transcription:

Welcome to DerekWeaver.com. In this video, we're going to replicate the "error open" code and the “error speed” code. We're going to use a W-957, without a hood, to demonstrate these errors and how to correct them; however, the troubleshooting and correction is applicable to both or to all three of our wheel balancers: the W-937, the W-957, and the W-977. View the full transcript here.